Solid-state batteries

One of the topics I’m working with, is the solid-state battery. We have recently started a new 4-year long EU project called SOLiD, which focuses on manufacturing of such batteries. You can find our website here. Make sure to bookmark it 😊

But what is a solid-state battery and why they are important?

And which challenges are still to be solved before they are used, for example, in cars?

Promise little – do much

As this is my first blog this year, I would like to start it with a short reflection to year 2022 and an outlook to 2023 before going into the solid-state battery topic. Last year, my personal theme was courage, and starting this blog was one part of that journey. The decision to do things even though it might be scary led to wonderful outcomes. Among many amazing things, I had my first live interview in TV, was elected as the research chair of BEPA Working Group of Raw Materials and Recycling, and just in the end of the year, I was promoted as a Principal Scientist at VTT. All this was much more than I even dared to dream of!

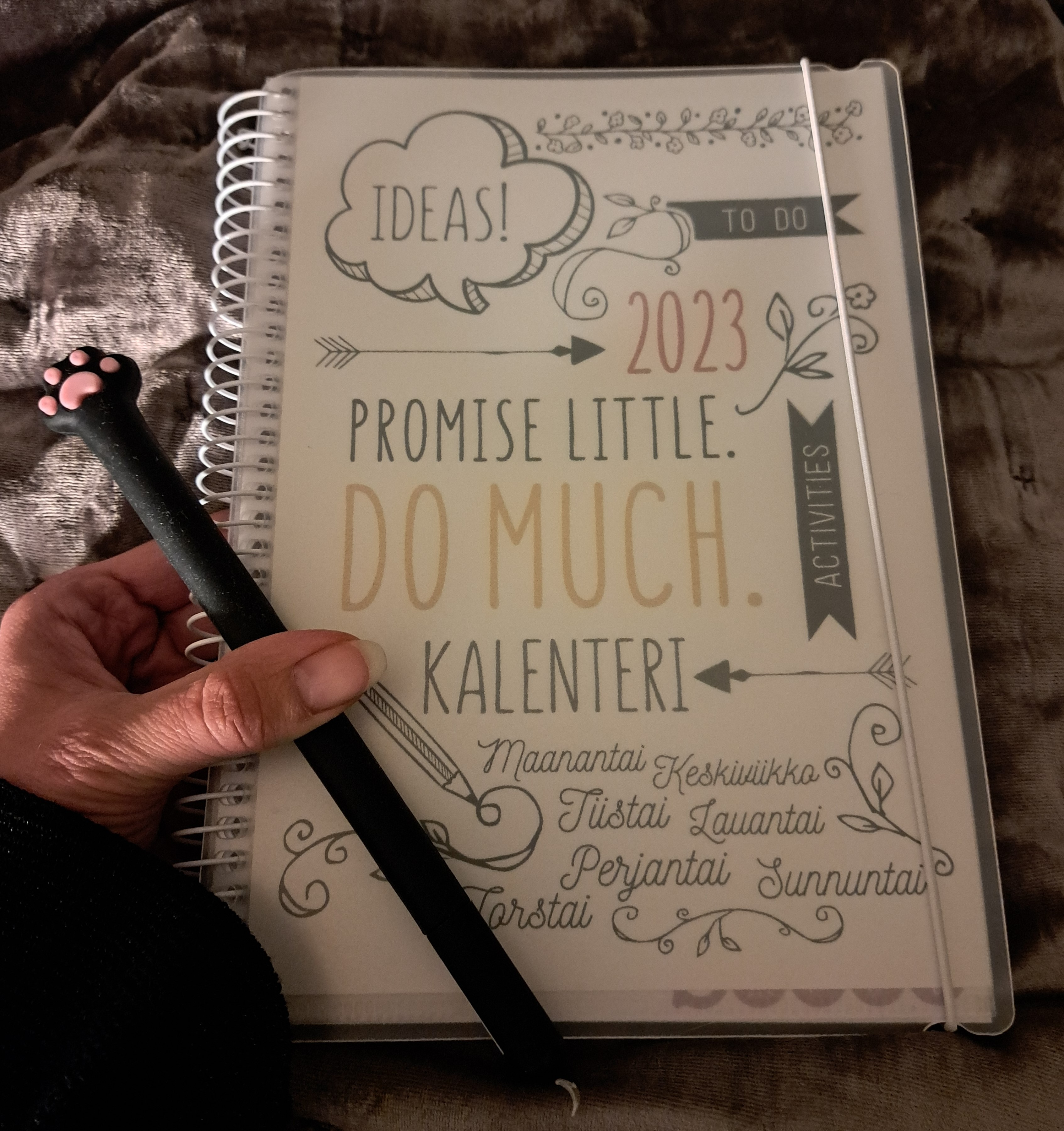

Now I’m very happy to be in a position where I can lead and work in projects that have a purpose and be part of the group in planning the future of batteries in Europe. As there are so many important activities ongoing, I decided that my theme for this year is “Promise little – do much”. I stole the idea from a calendar, which I bought for myself. This means that I will focus on getting things done in my current projects, and do not promise to participate in too many new (even though interesting!) activities.

Concretely, I want to make sure that I will be holding a well-working solid-state battery in my hands in the end of the year! Since so far in my projects, I have learned that making a good solid-state battery is not easy.

Benefits of solid-state batteries

Why we should then make solid-state batteries if it is so difficult. We already have well-working Li-ion batteries using liquid electrolytes on the market. Isn’t that enough?

Well, a liquid electrolyte has several benefits, such as high ionic conductivity and an established processing protocol. To work properly, the electrolyte must wet the battery electrodes and the separator well. As a liquid electrolyte can flow, it is relatively easy to fill in the pores of the electrodes and separator with it.

However, there are also some drawbacks. The liquid electrolytes, which are used in batteries, are flammable and they will form toxic gases when in contact with humidity from air. Thus, even though sealed well, there is always a risk for leakage and fire. Especially if the battery is damaged. A solid electrolyte is much safer as it does not flow, leak, or catch fire as easily as an organic liquid electrolyte.

The main benefit of solid-state batteries is their high energy density. This allows a longer driving range for an electric vehicle, and opens up new applications areas, such as electric trucks or even planes. A high energy density will also enable production of smaller battery-powered medical or wearable devices, which will be more comfortable for a user.

The reason for the high energy density of solid-state batteries is that a solid electrolyte enables the use of a dense lithium metal anode, instead of a porous graphite anode. A lithium anode takes much less space than a graphite one, but lithium metal is very unstable when in contact with a liquid electrolyte. Thus, a solid electrolyte is required. The interface between a solid electrolyte and lithium metal is much more stable, even though there is still a lot of work to be done to make it stable enough and achieve long lifetime.

Additional benefits of solid-state batteries include potential for lower carbon footprint of production and faster charging.

Differences between liquid and solid-state batteries

The main difference between conventional Li-ion batteries and solid-state batteries is indeed the state of the electrolyte. Li-ion batteries use a liquid organic electrolyte and solid-state batteries have a solid electrolyte.

Most of the commercially available batteries, such as electric vehicle batteries, are based on the liquid electrolyte. They are produced in factories with roll-to-roll coating methods, followed by automated cell assembly. Usually, the Li-ion cells contain a metal oxide cathode, polymeric separator, and a graphite anode – and everything is soaked with the liquid electrolyte.

Solid-state battery electrolytes are solid ionically conducting materials. There are a few different types of solid electrolytes, and they vary in mechanical and electrical properties. Common examples are conducting polymers and inorganic ceramic materials (oxides and sulphides). It is also possible to mix them together. The electrolyte functions also as a physical separator between the cathode and the anode. Thus, there is not necessarily a need for an additional separator layer.

As a polymer chemist/physicist, I’m most familiar with the polymer electrolytes. This is something we also decided to focus on in the SOLiD project.

The cathode can be the same in both solid and liquid electrolyte batteries. Thus, a solid-state battery does not reduce the need for cathode raw materials as the higher energy density and thus size reduction of the battery does not come from the cathode side.

The anode is different. Solid-state batteries aim at using a metallic lithium anode. Silicon is an option too. Using a graphite anode in solid-state batteries is not worthwhile as then we would not get any benefits in the energy density.

Challenges of solid-state batteries

As mentioned, one of the challenges in solid-state batteries is related to the interface between the solid electrolyte and the cathode and anode. During charging and discharging, a lot of material will travel from the cathode to the anode and back. The thickness of the Li anode will change significantly (several micrometres) during charging/discharging. As the electrolyte does not flow, it is challenging to maintain a good electrical and mechanical contact during cycling and avoid formation of voids at the interfaces.

Another issue is the formation of inactive lithium and lithium dendrites at the electrolyte/electrode interface. Even though a solid electrolyte will prevent dendrite formation due to its mechanical strength, it is not trivial to get a stable interface.

There would be also room for improving the ionic conductivity of the solid electrolytes, especially to reach room temperature operation.

Finally, solid-state batteries need a slightly different processing method than conventional Li-ion batteries. The solid electrolyte needs to be either mixed with the cathode active material before coating or infiltrated into the cathode after coating. Both are possible, but upscaling the process into an industrial scale needs still work.

Outlook

Even though there are challenges to be solved, the future of solid-state batteries looks bright. For example, in the SOLiD project, we are developing a scalable extrusion coating process for the cathode/polymer electrolyte blend and are utilizing pulsed laser deposition to add a stabilizing barrier layer on the lithium anode.

But this is only a small part. There is a huge amount of research ongoing in the field. Many companies are also developing solid-state batteries. You can find several examples from the brilliant Battery Report 2022, prepared by the Volta Foundation. The report also contains a lot of other interesting information and is a must-read for everyone who wants to follow what is going on in the battery field.

PS. If you are wondering how to build and measure solid state batteries for research purposes, I would recommend reading a paper called Critical Parameters for Evaluating Coin Cells and Pouch Cells of Rechargeable Li-Metal Batteries by Shuru Chen et al. I think it desribes very clearly how to make repeatable and reliable measurements with Li-metal cells.